An exceptional range of skills and experience

Kove offers an exceptional range of advanced skills and capabilities across a broad spectrum of engineering and design disciplines.

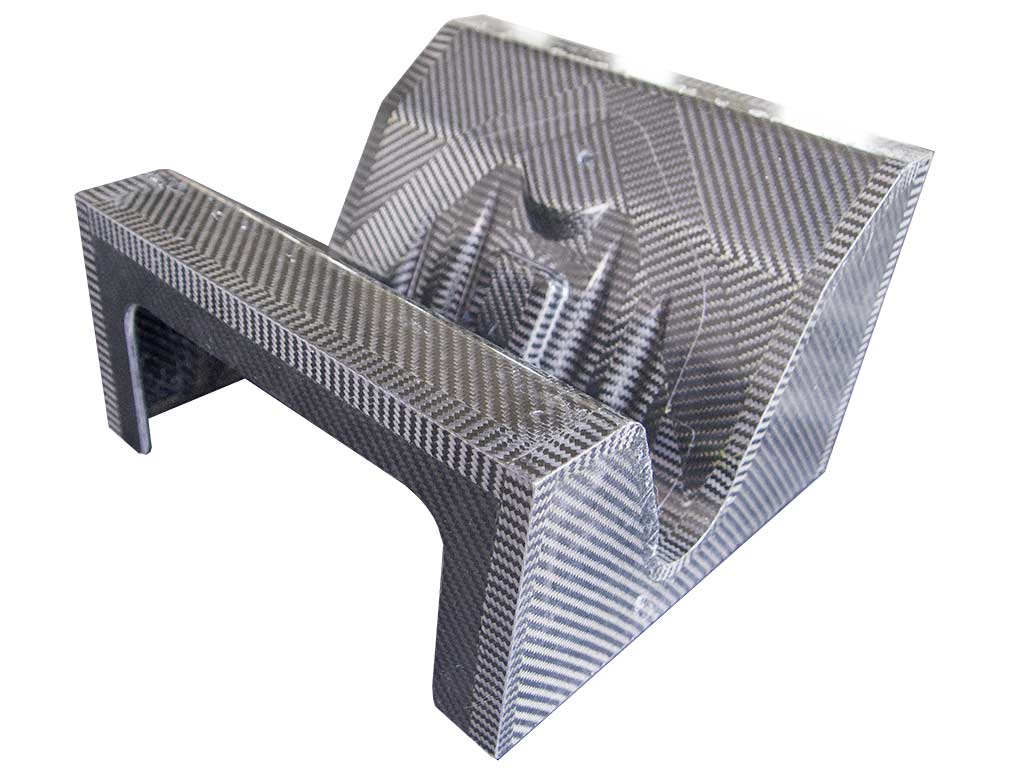

Composites

The innovative way that we use carbon composites sets us apart from others

Kove has many years experience designing and manufacturing composite structures and tooling for the high end automotive and motorsports sectors, including Formula 1.

|

|

We also have a strong partnership with SHAPE that gives us direct access to their composites manufacturing facility and a revolutionary process for manufacturing highly optimised carbon fibre preforms.

Unlike traditional woven and non-crimped fabrics, this process means that fibres can be aligned in any direction, offering unprecedented levels of part optimisation and allowing for the integration of complex local reinforcements. Further advantages include quicker processing time, higher production capability, easier material handling, reduced material and processing costs, and greater efficiency.

‘Our clients gain even greater access to leading-edge composite technologies, offering high quality, perfectly repeatable parts at a fraction of the costs and timescale of conventional manufacturing methods’

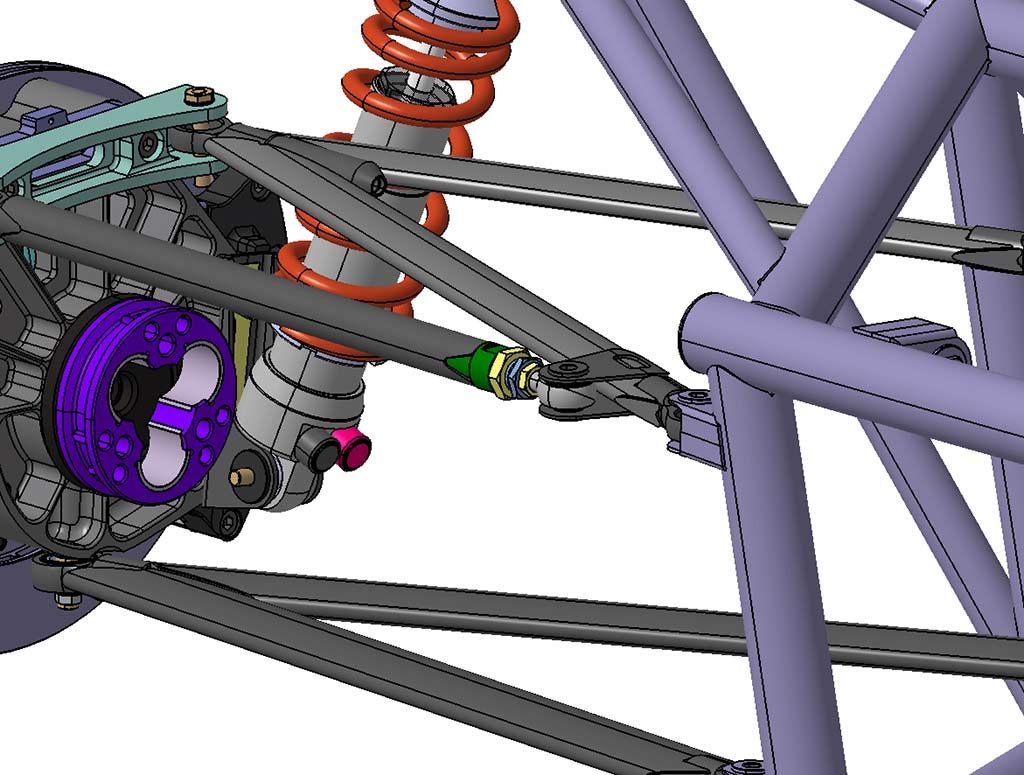

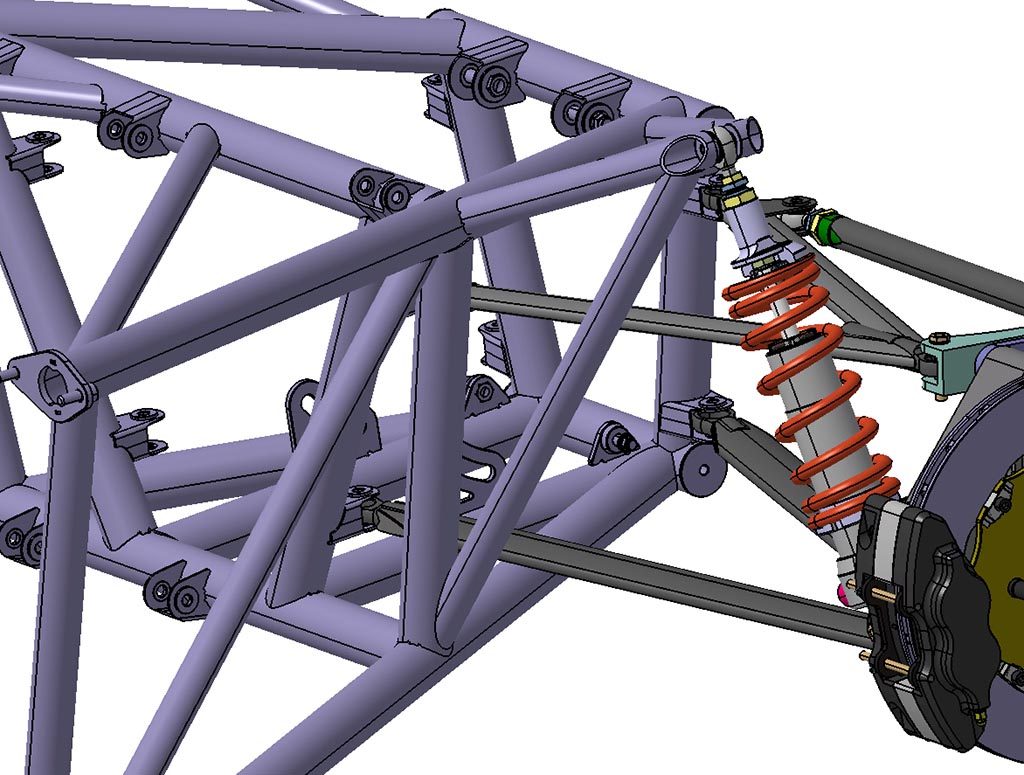

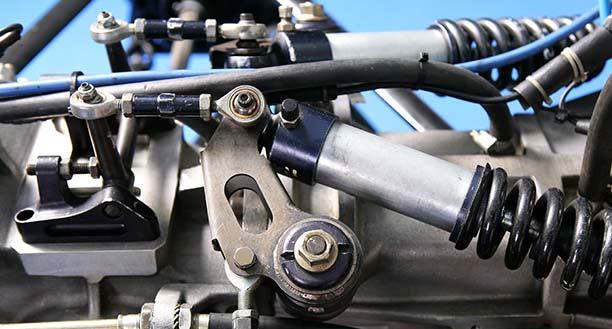

Vehicle dynamics

Kove is one of the leaders in vehicle dynamics

Kove’s co-founder John Begley is recognised as one of the leading experts in vehicle dynamics.

He has designed vehicle dynamics for F1, Formula E and some of the world’s most exotic supercars.

|

|

Building on John’s exceptional reputation, this is why many of the world’s most prestigious and high end automotive companies trust Kove to design their vehicle dynamics.

Packaging

Kove is known for its packaging design expertise

John Begley, Kove’s co-founder, is known across the industry for his exceptional packaging design skill. He is highly experienced in packaging mechanical and electrical systems into tight spaces without compromising the vehicle and thermal dynamics, and ergonomics.

Furthermore we often deliver packaging in conjunction with vehicle dynamics , creating exceptional, fully integrated design solutions.

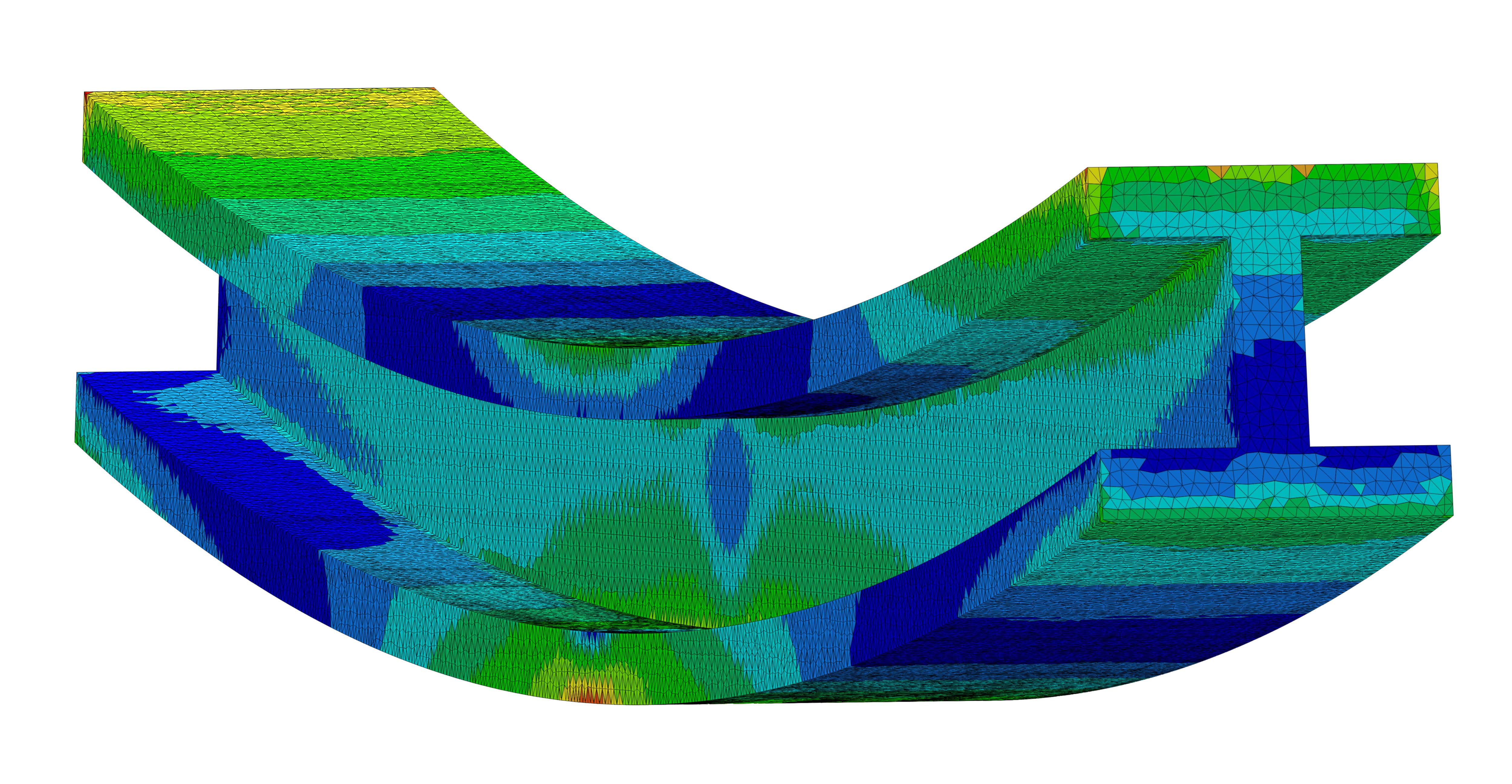

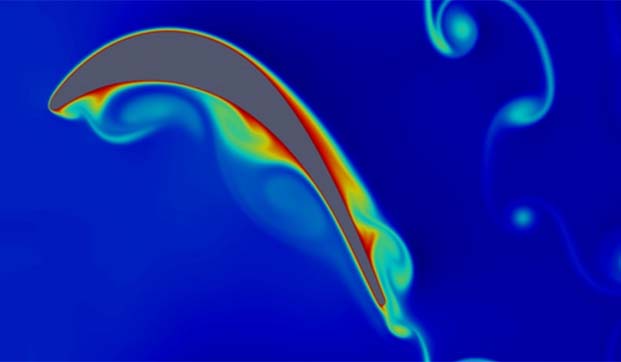

Analysis

We use leading edge testing and analytical technologies

Our suite of cutting edge design tools contain the built-in checks and balance that only the very latest computer technologies can offer. Designs are constantly verified against some of the most advanced testing algorithms in existence, meaning we can ensure the structural viability of any component well ahead of any physical production.

Another more specific area that we offer in conjunction with our partners is Full Finite Element Analysis (FEA) on Composite and Metallic structures.

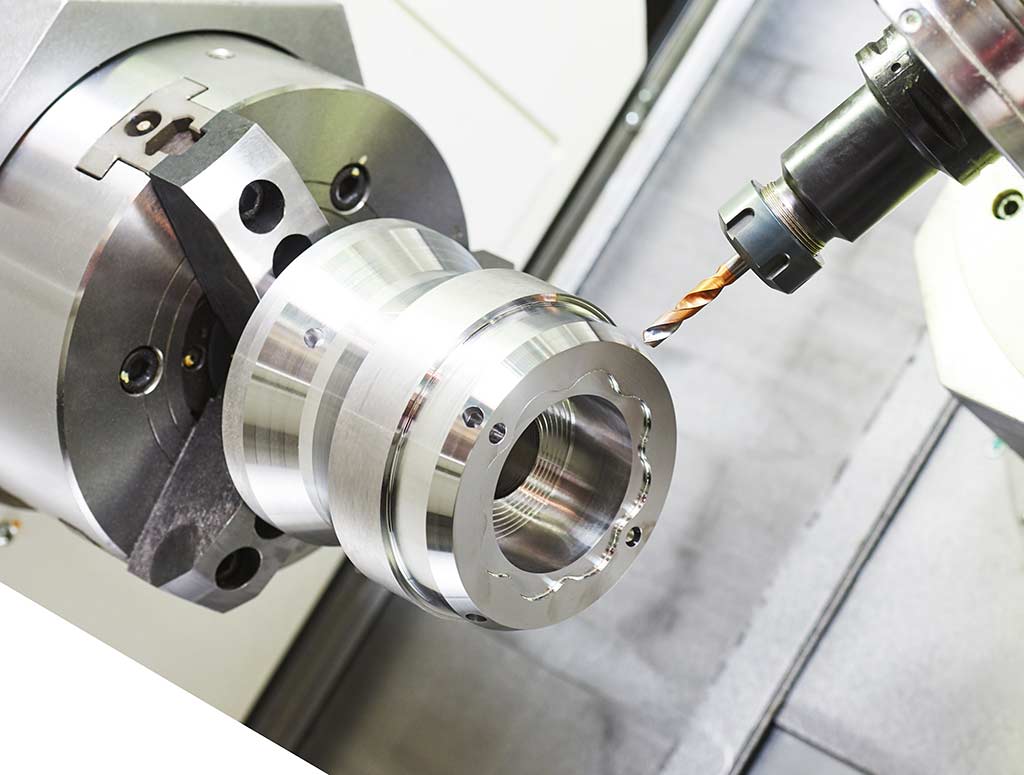

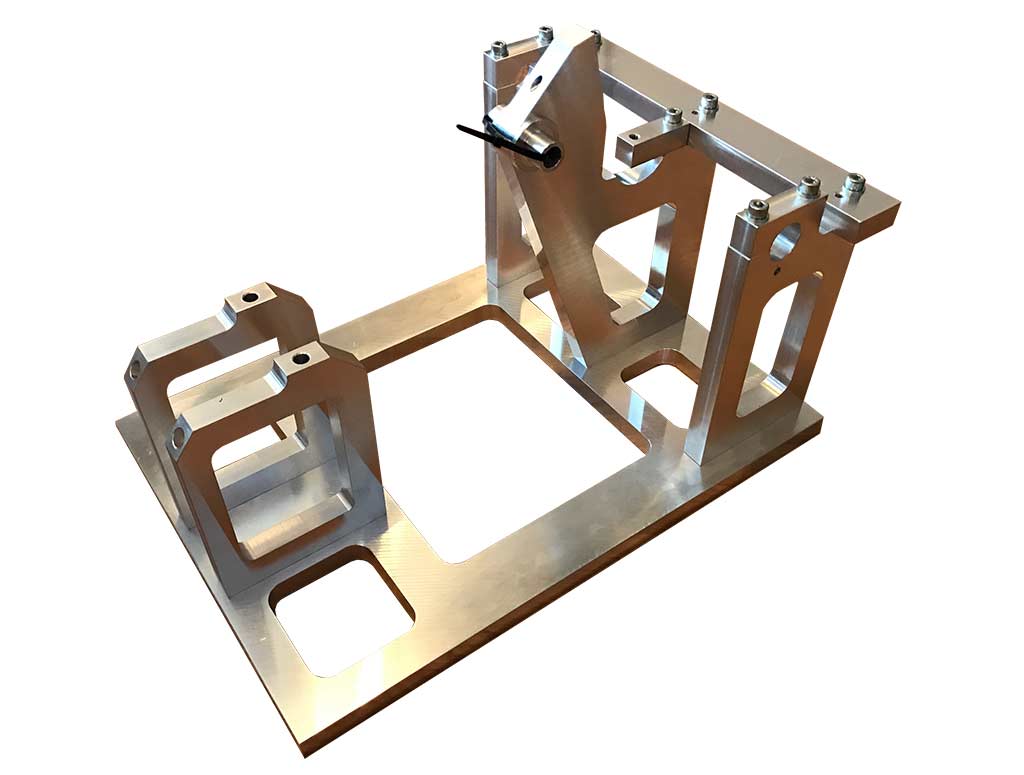

Machining & manufacturing

We are experts at using 3 and 5-axis machines to create tooling and parts

Over the years we have actively developed a series of partnerships that provide us with direct access to large machining resources and a large composite manufacturing facility. We stay actively involved throughout to ensure our rigorous quality standards are adhered to, costs kept under control and timescales met.

|

|

Kove also has access to a new state of the art composite material and manufacturing method developed by SHAPE. Manufacturing times are a fraction of more traditional methods, and the components produced are incredibly light, strong and cost effective.

Tooling

Kove has considerable expertise and experience in automotive, healthcare and aerospace tooling design

Kove has designed jigs, composites tooling and fixtures for a number of renowned companies across the automotive, healthcare and aerospace sectors.

That’s why, when one of our customers wanted bodywork tooling delivered in an exceptionally fast turnaround, they turned to Kove.

|

|

Part sourcing & procurement

We source and supply parts for our clients, especially where they have niche requirements that cannot be met in-house

We have a large and constantly updated database of UK based suppliers that allow us to meet the most demanding client needs whilst always ensuring the best value for money – hence why a major high-end automotive manufacturer recently entrusted Kove to supply a number of specialist parts for a prototype of their future vehicle programme.

As a further extension of our full end-to-end service offering, we also have a proven track record setting up procurement arrangements on behalf of our clients.

|

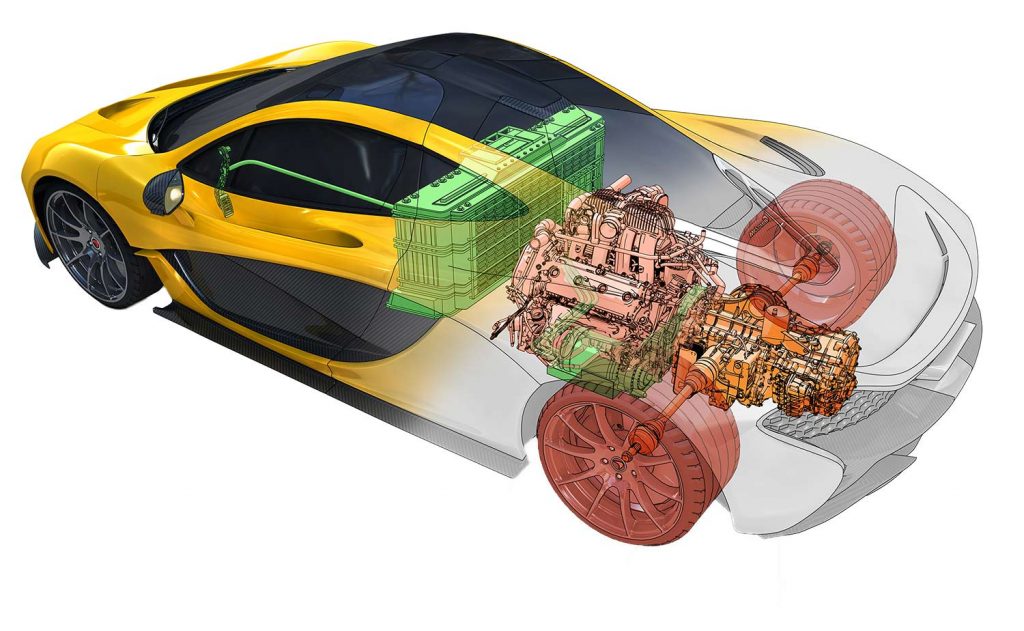

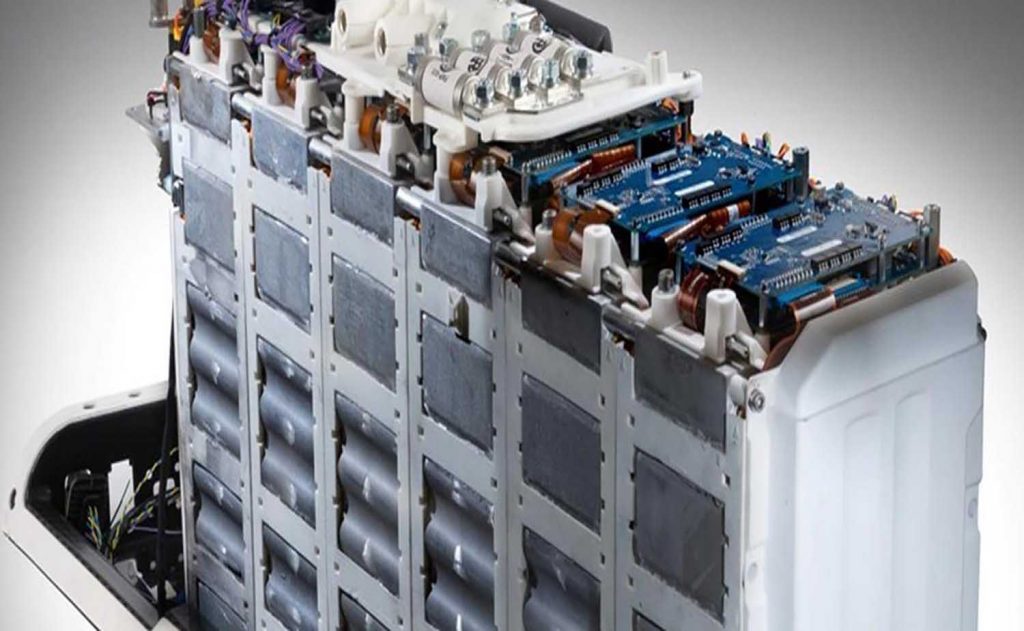

Hybrid technology

We have led the design of some of the most leading-edge and innovative hybrid technologies

We’ve led the design for some of the most leading-edge and innovative hybrid technologies, all because of our industry leading expertise in advanced materials and packaging. Hence why our co-founder Peter Kent was the lead engineer on the hybrid battery pack for the P1 Hypercar whilst at McLaren .

|

|

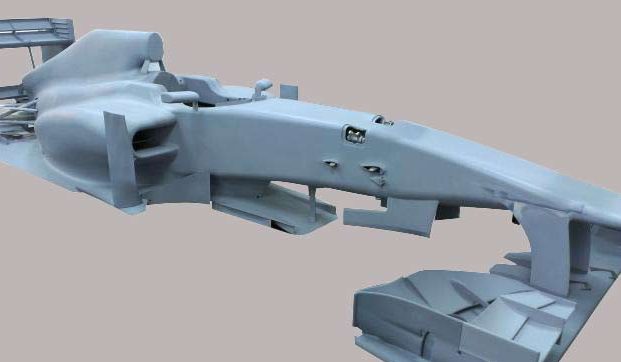

Vehicle aerodynamics & wind tunnel modelling

Kove has considerable aerodynamic design experience, especially in Formula 1 and high-end automotive

We have partnerships that give us access to some of the most highly advanced digital modelling software and CFD facilities.

Working with Mark Fowler of the Elemental Motor Company, John Begley and Peter Kent helped develop an innovative double diffuser that delivers unprecedented downforce levels at everyday driving speeds.

|

|

We also design and manufacture wind tunnel models. To date, these include the Marussia F1 car and a number of the latest McLaren supercars.